MIL-C-52128C

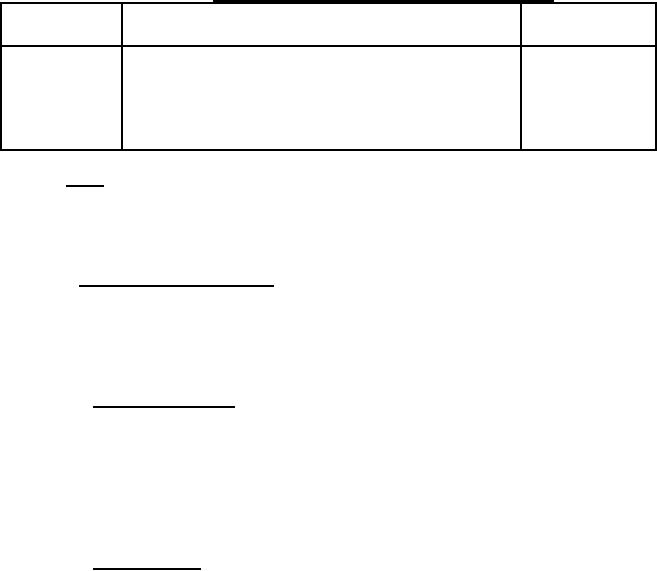

TABLE I. Examination schedule (Requirements) (Cont'd).

Requirement

Number

Characteristic

Paragraph

204.

Repair parts and maintenance tools not furnished as

specified.

3.28

205.

Toolbox not as specified.

3.29

Workmanship not as specified.

3.32

206.

4.6.2 Tests. Prior to test, the crusher shall be lubricated with military oils and greases

specified in 3.20. Oils shall be those designated for use in the ambient temperature at which the

test is being performed. The contractor shall furnish equipment to feed crusher and portable

conveyors to carry away crushed material during test.

4.6.2.1 Test conditions (operating). The crusher shall be tested either as a unit as specified

in 3.1.1, or as a plant with a secondary crusher as specified in 3.1.1. Quarry rock shall be of the

material as specified in 3.1.1.1 containing some rock 18 inches by 34 inches. Only that

maintenance established by the contractor and submitted as a maintenance schedule prior to the

tests shall be performed during the test.

4.6.2.1.1 Percentage of crush. Arrange the flow of material so that all material passing

through the vibrating grizzly bars will be discharged to the stub conveyor or chute. Weigh not

less than 100 tons of crushed material discharged from the delivery conveyor. The material

bypassed through the grizzly bars shall be weighed separately and should not exceed 20 percent

of the combined total of material from the discharge chute and the delivery conveyor. Presence

in the feed of more than 20 percent of material not requiring crushing shall constitute failure of

this test.

4.6.2.1.2 Operating time. Crushed rock production capacity shall be computed on the basis

of net operating time which shall be defined as gross operating time less allowable down time for

the following:

(a) Jamming from rock fragments larger than the maximum size of rock specified

in 3.12.

(b) Delay due to lack of material delivery to the crusher.

(c) Normal machinery maintenance (lubrication, jaw setting adjustments, takeups)

(down time due to any design deficiency shall not be considered normal

maintenance).

(d) Other conditions considered by the contracting officer to be beyond the control of

the contractor.

Down time required for maintenance other than lubrication and operating adjustments shall be

considered as net operating time. Down time caused by design deficiencies or failure of parts

not classified as high mortality parts shall constitute failure of any test.

38

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business